How RH Used AI Agents to Enable Autonomous Procurement

Noam Shakuri

TL;DR

RH Electronics, a global subcontractor and one of Israel's largest electronics subcontractors, transformed their procurement operations by deploying AI agents that automate supplier communication.

The challenge: Manual processes required 3 days to distribute purchase orders to 1,000+ suppliers, with hours spent entering responses into their ERP system.

The solution: Evolinq's autonomous AI agents work within existing email workflows, reading supplier responses in any format (Excel, PDF, text) and automatically updating the ERP system.

The results: Distribution reduced from days to a single button click, 25,000+ purchase order lines automated, proactive risk alerts 2-3 weeks before delivery dates, reduced shortages and delays, shortened PO cycle time, reduced overstock, and zero supplier workflow disruption. Deployed in just a couple of days with no ERP integration required, the system transformed a 35-person procurement team from clerical data entry to strategic supplier management. With Evolinq, RH now operates primarily a strategic procurement function, with a supply chain that is not only autonomous but also flexible and agile to disruptions.

When Manual Processes Can't Scale with Growth

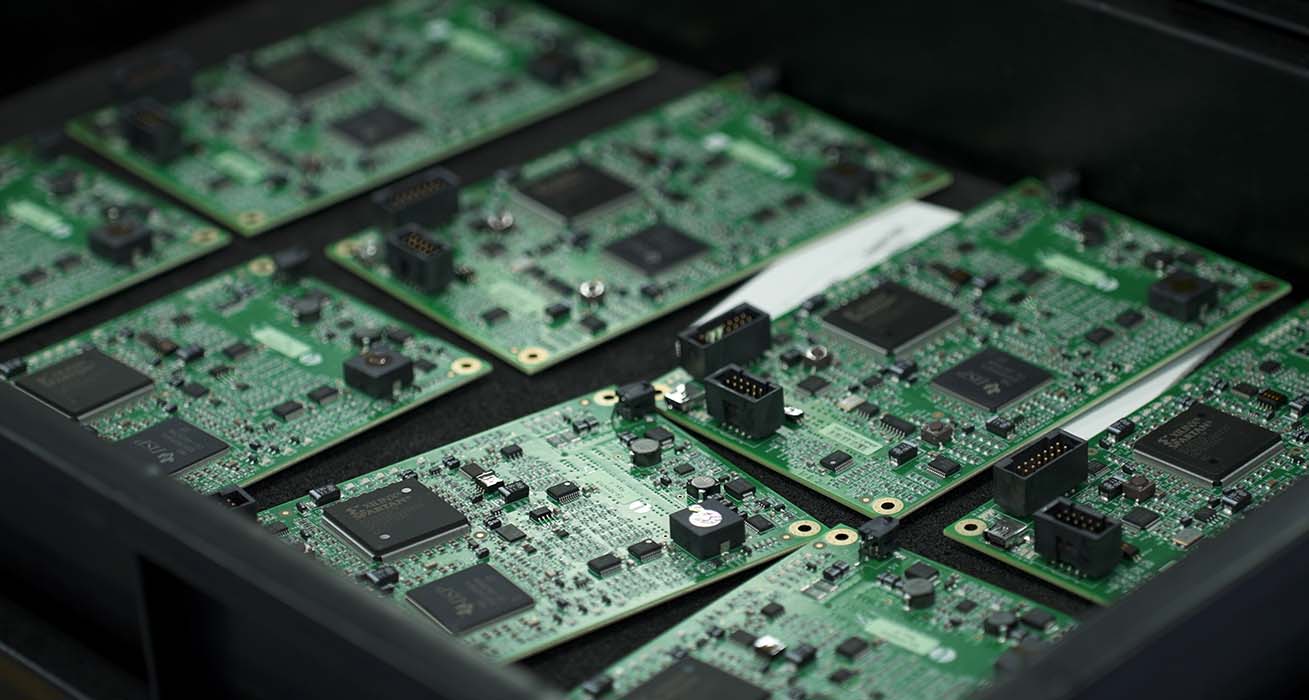

As one of Israel's largest subcontractors with over 40 years in the electronics manufacturing industry, the company manages an intricate web of 1,000+ suppliers across Israel, Romania, and the United States. Their procurement team processes more than 15,000 unique SKUs, with 25,000 active purchase order lines in play at any given moment.

The complexity alone would challenge any procurement operation. But for RH, the real bottleneck wasn't the volume - it was how they were managing it.

"The team was incredibly frustrated with the entire distribution process," recalls Erika Abelis, Purchase Manager overseeing 35 procurement and import/export staff. "For large projects, it would take about three days of manual work."

That three-day timeline? It was just for distributing purchase orders to suppliers. The procurement buyer would manually cut rows from Excel files at the supplier level and paste them into individual emails. Then came the reverse process: collecting supplier responses, reading each one, manually entering delivery dates into their ERP system, and tracking exceptions.

The cascading impact was severe:

- Human error multiplied: Manual data entry across 7,000 rows created inevitable mistakes - wrong dates, missed updates, lost communications

- Zero proactive visibility: Problems surfaced at the last minute, often on delivery day, when it was too late to find alternative suppliers

- Production stoppage risk: For a manufacturer where 70% of costs are procurement-related, a single missing component could halt entire production lines

- Team burnout: Skilled procurement professionals spent days on clerical work instead of strategic supplier management

- Inconsistent supplier communication: Each buyer had their own report format and communication style, creating confusion for suppliers

For companies with single-source suppliers for critical components, the stakes were even higher. "If an order doesn't arrive, in most cases we have nowhere else to source the inventory," Erika explains. "It could lead to production stoppages and, with some customers, even penalties."

RH manages over 15,000 unique SKUs with 25,000 active purchase order lines - where "a single missing component could halt entire production lines."

RH manages over 15,000 unique SKUs with 25,000 active purchase order lines - where "a single missing component could halt entire production lines."

The Search for Autonomous Procurement: What RH Needed

Shiri Ashton, Operational Purchase Team Leader with 20 years of procurement experience, had seen various procurement technologies come and go. When she joined RH, she expected more of the same manual processes she'd encountered elsewhere.

Instead, she discovered a company culture committed to innovation. "I came to RH and realized there's work here that's different from what I'm familiar with," she notes. "More advanced work, more innovative and modern, and it streamlines work significantly."

But even with that innovative mindset, the procurement team faced a fundamental challenge: How do you automate supplier communication when suppliers use different formats, communication styles, and workflows?

Traditional supplier portals require:

- Complex ERP integrations (months of IT work)

- Forcing suppliers to adopt new platforms

- Standardized data entry formats

- Significant change management

RH needed something different: a solution that could work within existing communication channels - email, Excel files, even PDFs - without requiring suppliers to change anything about how they operated.

As CEO Amir Eliyahu put it, the ability to bring AI and specialization tools into procurement operations would provide a unique advantage in delivering better service chains to customers. With procurement representing 70% of company expenses, this wasn't just an efficiency project - it was a strategic priority.

Manual data entry across 7,000 rows created inevitable mistakes - wrong dates, missed updates, lost communications

Manual data entry across 7,000 rows created inevitable mistakes - wrong dates, missed updates, lost communications

The Evolinq Implementation: Autonomous AI Agents in Action

RH allocated one month for implementation. The actual timeline? One week to full deployment.

"I have to say, I felt like they were working only for us," Erika recalls. "The availability was immediate, and together we went through all the issues, refined things, and adapted everything to the organization's needs."

What made deployment so rapid was Evolinq's architectural approach: Autonomous AI agents that operate within existing workflows rather than replacing them.

How the AI Procurement Agents Work

Instead of forcing a new supplier portal, Evolinq's AI agents mimicked how human procurement buyers already operated:

- Automated distribution: The system autonomously distributes purchase order rows to the appropriate suppliers via email - replacing the manual process

- Intelligent communication: Agents send supplier-specific communications on behalf of the buyers in a standardized format, maintaining consistency across all procurement staff members

- Multi-format response handling: AI agents read supplier responses, whether they arrive as Excel files, PDFs, or email text

- Contextual data extraction: The system identifies delivery confirmations, delays, pricing changes, and exceptions without human intervention

- Automated ERP updates: Confirmed data loads directly into RH's ERP system, eliminating manual re-entry

- Proactive alerts: When suppliers flag delays or production issues, the system immediately notifies buyers with time to source alternatives

The supplier experience? Seamless.

"Suppliers didn't feel the Evolinq system at all," Erika emphasizes. "From their perspective, they continued receiving emails from the team, from the same buyer working with them. Their experience as a supplier was very positive."

This was critical. With 1,000+ suppliers, forcing workflow changes would have created resistance, training overhead, and adoption delays. Instead, suppliers continued their normal processes while RH gained unprecedented automation and visibility.

Measurable Results: From Reactive to Proactive Procurement

Time Efficiency Transformation

Before Evolinq:

- days of manual work to distribute purchase orders for large projects

- Hours spent manually entering supplier responses

- Line-by-line review of many items per supplier response

After Evolinq:

- Autonomous distribution to all suppliers

- Automated response processing and ERP loading

- AI-flagged exceptions requiring human attention only

"It's day and night," Shiri states simply. "Before, it was truly Sisyphean work - very frustrating. Without the Evolinq system, the work is frustrating. It drags on for hours and sometimes days depending on the volume of lines each buyer has."

The time savings compounded. For RH's operational procurement team managing approximately 2,000 active purchase order lines (out of 25,000 total), the elimination of clerical work meant buyers could focus on the 5-10% of orders with genuine issues requiring strategic intervention.

Supplier Performance Improvements

Within months of deployment, RH measured tangible supplier behavior changes:

- Reduced shortages and delays: Proactive visibility and automated follow-up have significantly reduced component shortages and delivery delays

- Shortened PO cycle time: The automation of distribution and response processing has dramatically shortened the entire purchase order cycle from days to hours

- Reduced overstock: Better visibility into supplier confirmations and delivery schedules has enabled more accurate inventory planning, reducing excess stock levels

- Faster supplier confirmation times: Average response time to initial purchase orders decreased significantly

- 3-day turnaround standard: For TAPI reports (supplier delivery confirmations), RH now provides responses within three days - with AI immediately flagging problems and non-aligning items

- Proactive exception handling: Instead of discovering delays on delivery day, the system alerts buyers weeks in advance when suppliers flag production issues or schedule changes

- Extended planning horizon: Procurement can now distribute reports covering 6-month forward-looking periods instead of just 2 months, giving suppliers more response time and enabling better capacity planning

"The department's metrics improved significantly," Erika confirms. "Whether in confirming delivery dates, material collection, or verifying arrivals."

Risk Mitigation and Production Continuity

For a manufacturing operation where component shortages can halt production lines, the shift from reactive to proactive risk management was transformative.

The AI agents provide:

- Immediate delivery delay visibility: Red-flagged items in reports give buyers 2-3 weeks to source alternatives instead of same-day scrambling

- Pastdue order tracking: The operational procurement team is measured on orders in "Pastdue" status (delivery date passed). Evolinq's automated supplier follow-up ensures these items don't fall through the cracks

- Warehouse coordination: The dashboard allows managers to filter all items arriving on specific dates, enabling reception teams to prioritize critical components

"The system allows me as a manager to cut all the items that should arrive according to a specific date and then also focus the warehouse reception on receiving the required items," Erika explains. "We can manage material more correctly, further in advance, and not just see the range of the next two months but see the end of the horizon."

Dashboard-Driven Management Visibility

For management, Evolinq's dashboard transformed procurement oversight from periodic check-ins to real-time operational intelligence.

"Every morning I can come to work, enter the Evolinq dashboard system, and see all the lines that aren't converging for me in a focused way according to customer," Erika describes. Key metrics accessible instantly:

- Lines distributed per buyer, per customer, per supplier, per project

- Unconfirmed orders requiring follow-up

- Orders due by specific date ranges

- Supplier performance patterns (on-time vs. delayed deliveries)

- System usage by team member

"I can see at any given moment that the information fed into our ERP system is the most reliable information," she adds.

For Shiri, the dashboard solved team management challenges too: "I don't need to ask a lot of questions. I can check: Did you send it? I already see if you sent it or not. I can know if the work was done or not and when."

The transparency benefited everyone. Team members knew their work was visible, creating accountability. Managers could identify coaching opportunities without micromanaging. And executives gained confidence in procurement data accuracy.

The Broader Implication: Autonomous Procurement at Scale

RH electronics' experience demonstrates what's possible when AI agents handle procurement communication overhead at scale.

The key insights for procurement leaders evaluating similar transformations:

1. Supplier adoption isn't the bottleneck when AI works within existing channels: Traditional supplier portals fail because they force suppliers into new workflows. Autonomous agents that operate via email and handle unstructured responses (Excel, PDF, text) eliminate adoption friction entirely.

2. Deployment speed depends on integration requirements: RH went from planning to production in two weeks because Evolinq required zero ERP integration for core functionality. The system works alongside existing systems rather than replacing them.

3. Team capacity constraints dissolve when clerical work disappears: A 35-person procurement team managing 1,000+ suppliers and 25,000+ lines isn't understaffed - the work was just structured inefficiently. Automating communication overhead revealed massive untapped capacity for strategic work.

4. Proactive risk management requires real-time visibility: The shift from discovering delays on delivery day to receiving alerts 2-3 weeks in advance fundamentally changes supply chain risk management. That visibility only comes from systems processing supplier communications the moment they arrive.

5. Management dashboards enable coaching, not micromanagement: When managers can see work completion patterns without interrogating team members, they can focus on helping people improve rather than verifying task completion.

"There's constant thinking about how to streamline work, how to utilize time, and how to work with innovation," Shiri reflects. "And Evolinq is a good example of how we streamline and how we work with innovation."

With Evolinq, RH has transformed their procurement function into primarily a strategic operation. By eliminating manual clerical work and automating supplier communication, the procurement team now focuses on strategic supplier relationships, negotiation, and supply chain optimization. The autonomous AI agents have not only made RH's supply chain autonomous but also flexible and agile to disruptions. When suppliers flag delays or production issues, the system immediately alerts the team, enabling rapid response and alternative sourcing strategies. This agility has proven critical in an environment where supply chain disruptions can halt entire production lines.

For Amir Eliyahu, the CEO, the strategic logic was clear: with procurement representing 70% of company expenses and supplier management critical to customer service, bringing AI capabilities to this function wasn't optional - it was a competitive advantage.

Your Procurement Transformation: What's Possible?

RH' journey from days of manual processes to single-button automation demonstrates what autonomous AI procurement agents can achieve when deployed thoughtfully.

"If you work together with an AI system and you apply thinking, you really develop," Shiri concludes. "And for us as a company and within the team, it only does good, because it saves time that's really wasted. And it pushes us forward several steps and gives us tools for efficient and fast work."

The results weren't incremental - they were transformative:

- 25,000+ purchase order lines automated

- 1,000+ suppliers managed without workflow disruption

- Proactive risk detection weeks before delivery dates

- Reduced shortages and delays through automated follow-up and early warning systems

- Shortened PO cycle time from days to hours

- Reduced overstock through improved visibility and planning

- Team capacity redirected from clerical to strategic work

- Supply chain transformed to be autonomous, flexible, and agile to disruptions

- 2-week deployment with zero ERP integration

See how your procurement team can achieve similar results with 1-day deployment.

Evolinq's autonomous AI agents work within your existing communication channels - no supplier portals, no months-long implementation, no forced workflow changes. Just immediate automation of supplier communication overhead and real-time supply chain visibility.

Request a demo to experience how autonomous procurement agents handle your supplier communications while your team focuses on strategic decisions.

About RH Electronics

RH Group is one of Israel's largest subcontractors in electronics manufacturing, with over 40 years of industry experience. Operating facilities in Israel, Romania, and the United States, RH manages complex procurement operations across 1,000+ global suppliers supporting diverse manufacturing projects. The company's commitment to operational innovation and supply chain excellence drives continuous improvement in procurement efficiency and customer service delivery.